Mocheso Shrink Insulation Breakout

Kopo

1.E sebelisoa bakeng sa motlakase o mahareng ho fihla ho 36kV

2.Tshireletso khahlanong le mongobo le khatello

3.E loketse ho arohana ha cable ho khaotsa

Sebopeho

Sekhomaretsi sa 1.Hot melting se fana ka metsi a betere

Mofuta oa ho roala: ho roala filimi

2.Ho hanyetsa kutu e ntle haholo

3.UV ho hanyetsa

4.E phahametse metsi

5.Lintho tse phahameng tsa motlakase le tsa mechine

6.Easy tlhomamiso

Sebopeho

1.Mosebetsi o ratoang oa lisebelisoa tsa motlakase

2.Reliable insulation

3.Superior hermetic ho tiisa

4.Mocheso o babatsehang / bopaki bo batang, bo sa keneleng metsi, Anti-botsofali ,

5. E sebelisoa haholo tšimong ea matla a motlakase, elektroniki, petroleum, boenjiniere ba lik'hemik'hale, kaho le puisano.

Tlhahiso ea li-tubing tse nyenyefatsang mocheso e tlameha ho qala ka ho khetha masterbatch e nepahetseng, ebe o khetha lisebelisoa tse thusang ho hlahisa tse khethehileng.

Thermal housing casing.

1. Ts'ebetso ea tlhahiso ea mocheso o fokolang mocheso ke oa pele oa tlhahiso ea polyene leech masterbatch: ho kopanya lisebelisoa tse fapaneng tsa polyene leech le lisebelisoa tse fapaneng tse thusang.

Lisebelisoa li lekanngoa ho ea ka karo-karolelano ea foromo ebe li kopantsoe: lisebelisoa tse tsoakiloeng li kenngoa ka har'a mafahla-screw extruder le pelletized ho hlahisa polyene leech functional masterbatch.

2. Mokhoa oa ho bopa sehlahisoa: ho ea ka sebōpeho sa sehlahisoa, mekhoa e 'meli ea extrusion e le 'ngoe ea screw extrusion le ente ea ente e ka sebelisoa.

Bakeng sa ho sebetsa le ho hlahisa:

1. Mofuta o le mong oa "screw extrusion": o sebelisoa haholo bakeng sa ho etsa liphaephe tse silang mocheso, joalo ka liphaephe tse nang le lebota le le leng tse honyehang mocheso, lithapo tse habeli tse honyehang mocheso tse nang le sekhomaretsi, le botenya bo mahareng.

Liphaephe tse silang mocheso oa lebota, liphaephe tse tebileng tsa mocheso oa busbar, liphaephe tsa mocheso o phahameng tse honyehang le lihlahisoa tse ling kaofela li sebetsoa le ho etsoa ke sekoti se le seng.

Mohala oa tlhahiso ea li-tube tse chesang mocheso o lokela ho ba le lisebelisoa tse latelang: extruder (ho etsa li-tube tsa mocheso), hlobo ea tlhahiso, tanka ea metsi a pholileng, sesebelisoa sa tsitsipano, le

Sesebelisoa sa Disk, joalo-joalo.

2. Ho bopa ka ente: haholo-holo e sebelisetsoang tlhahiso ea likarolo tse khethehileng tse nang le mocheso, tse kang likatiba tsa mocheso, likhele tse khonang ho honyeha, libethe tsa monoana tse theolelang mocheso le lihlahisoa tse ling.

Kaofela ba sebelisa mochini oa ente, 'me lisebelisoa tsa tlhahiso li lokela ho kenyelletsa mochini oa ente le hlobo.

3. Mohato o latelang oa bohlokoa ke ho kopanya mahlaseli.Lihlahisoa tse entsoeng ka extrusion kapa ente molding e ntse e le mehala ea limolek'hule.

Sebopeho, sehlahisoa ha se e-s'o be le "mosebetsi oa memori", mme ts'ebetso ea ho hanyetsa mocheso, ho hanyetsa botsofali, le ho apara ho hanyetsa ha hoa lekana.

Fetola sebopeho sa limolek'hule tsa sehlahisoa.Mokhoa oo re tloaetseng ho o sebelisa ke phetoho ea radiation crosslinking: electron accelerator radiation crosslinking, cobalt source radiation.

Cross-linking, peroxide lik'hemik'hale sefapano se kopanyang, ka nako ena molek'hule e fetoha ho tloha mohahong oa limolek'hule ho ea mohahong oa marang-rang.Lihlahisoa tse fetisitsoeng lia feta

Ka mor'a ho hokahanya, e na le "phello ea mohopolo", e leng ho matlafatsang haholo ho hanyetsa mocheso, thepa ea mechine, le lik'hemik'hale tsa lik'hemik'hale tsa mocheso o fokolang mocheso.Tafole e khethehileng

Hona joale tube ea sink ea mocheso e fetohile ho tloha boemong ba ho mamellana ho ea ho e sa lumellaneng, ho tsofala ho hanyetsa, ho hanyetsa abrasion, le lik'hemik'hale tsa corrosion resistance.

4. Katoloso ea ho bopa: Sehlahisoa se fetotsoeng ke radiation crosslinking se se se na le "sebopeho sa mohopolo oa sebopeho", 'me se na le matla a holimo.

Ts'ebetso e sa qhibiliheng tlas'a mocheso.Kamora ho futhumatsa ka mocheso o phahameng, ho phatloha ha vacuum le ho pholile, e fetoha tube e phethiloeng ea mocheso, ebe ho latela tube.

Boemo ba sebele ba ho paka le ho koala sehlahisoa se felileng le bona bo ka khaoloa le ho hatisoa ho latela litlhoko tsa bareki.Sephutheloana se tloaelehileng se sa nke lehlakore se fumaneha hape.

Tshebetso

| Teko | Mokhoa oa Teko | Tlhokahalo |

| Matla a tšepe | ASTM D2671 | ≥13 Mpa |

| Ho lelefatsa nakong ea khefu | ASTM D2671 | >300% |

| Matla a thata ka mor'a ho tsofala ha mocheso | ASTM D 2671/120℃,168h | ≥10 Mpa |

| Elongation nakong ya khefu ka mora ho tsofala ha mocheso | ASTM D 2671/120℃,168h | ≥250% |

| Ho hanyetsa molumo | Tlhaloso: IEC 93 | >1014Ω.m |

| Matla a dielectrical | Tlhaloso: IEC 243 | ≥15KV/mm |

| Sekhahla sa ho monya metsi | ISO 62 | ≤0.1% |

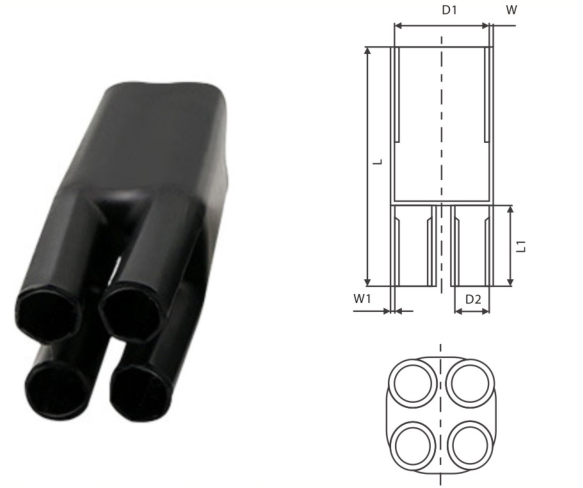

| Mofuta | D1 (mm) | D2 (mm) | W (mm) | W1 (mm) | L (mm) | L1 (mm) | ||

| E atolositsoeID(mets) | E hlaphohetsoeID(mets) | E atolositsoeID(mets) | E hlaphohetsoeID(mets) | Lebota le Hlabollotsoeng Botenya(mets) | E hlaphohetsoe Bolelele(mets) | |||

| 2-cores |

|

|

|

| ||||

| TZ-2.0 | 20 | 14 | 11 | 3.5 | 3 | 2.2 | 110 | 40 |

| TZ-2.1 | 25 | 16 | 16 | 5 | 3 | 2.2 | 110 | 40 |

| TZ-2.2 | 40 | 20 | 25 | 7.5 | 3 | 2.2 | 140 | 50 |

| TZ-2,3 | 50 | 35 | 30 | 12 | 3.5 | 2.5 | 140 | 50 |

| 3-cores | ||||||||

| TZ1-3.0 | 35 | 18 | 15 | 4 | 3 | 2.2 | 135 | 50 |

| TZ1-3.1 | 40 | 20 | 18 | 5 | 3 | 2.2 | 135 | 50 |

| TZ1-3.2 | 55 | 26 | 23 | 6.5 | 3 | 2.2 | 155 | 50 |

| TZ10-3.1 | 70 | 29 | 32 | 7.5 | 3 | 2.5 | 190 | 70 |

| TZ10-3.2 | 90 | 44 | 39 | 12.5 | 3 | 2.5 | 190 | 70 |

| TZ10-3,3 | 105 | 49 | 50 | 14.5 | 3.5 | 3 | 210 | 70 |

| TZ10-3,4 | 120 | 68 | 62 | 22 | 3.5 | 3 | 210 | 80 |

| 4-cores | ||||||||

| TZ-4.0 | 35 | 18 | 12.5 | 3.5 | 3 | 2.2 | 130 | 50 |

| TZ-4.1 | 44 | 21 | 17 | 5 | 3 | 2.2 | 150 | 60 |

| TZ-4.2 | 60 | 29 | 25.5 | 7.5 | 3 | 2.2 | 165 | 60 |

| TZ-4,3 | 71 | 41 | 32 | 11 | 3.5 | 2.5 | 190 | 70 |

| TZ-4,4 | 84 | 42 | 36 | 12 | 3.5 | 2.5 | 190 | 70 |

| 5-cores | ||||||||

| TZ-5.0 | 33 | 21 | 12 | 3.5 | 3 | 2.2 | 125 | 50 |

| TZ-5.1 | 51 | 25 | 14 | 5 | 3 | 2.2 | 160 | 60 |

| TZ-5.2 | 80 | 31 | 25 | 7.5 | 3 | 2.2 | 170 | 70 |

| TZ-5.3 | 95 | 47 | 32 | 11 | 3.5 | 2.5 | 180 | 70 |

P: NA U KA RE THUSA HO Ntlafatsa LE HO ROMELA KA NTLE?

A: Re tla ba le sehlopha sa litsebi ho u sebeletsa.

P: O NA LE LITITIFIKA ENG?

A: Re na le litifikeiti tsa ISO, CE, BV, SGS.

P: NAKONG YA HAO YA WARANTI KE EFE?

A:1 selemo ka kakaretso.

P: NA U KA ETSA TŠEBELETSO EA OEM?

A: E, re ka khona.

P: U TSAMAISA NAKO EFE?

A: Mefuta ea rona e tloaelehileng e teng, ha e le liodara tse kholo, ho nka matsatsi a ka bang 15.

P: A O KA FANA disampole tsa MAHALA?

A: E, ka kopo ikopanye le rona ho tseba mohlala oa pholisi.