Socket Clevis ke eng?

Socket clevis e boetse e tsejoa e le socket tongue ke karolo ea bohlokoahali ea theknoloji ea pole line.

E sebelisoa hangata lithapong tse holimo, lithapong tsa phetiso le lithapong tsa motlakase.

Ke karolo e kholo ho li-pole line hardware eo hangata e hokelang insulator ea mofuta oa sokete le lets'oao la tsitsipano.

Sheba sena:

Khokahano ea socket clevis e fapana linaheng tse fapaneng ho latela melao e laolang theknoloji ea pole line.

Kahoo, ho bohlokoa ho tseba khokahanyo naheng ea heno pele u etsa qeto ea ho beha taelo ea hardware.

Mohlala, Afrika mofuta oa socket clevis o sebelisoang o kenyelletsa:

Leleme la sokete le sebelisitsoe ka nepo ho "Aluminium Conductor Steel Reinforced (ACSR)".

Bophara ba ka ntle bo pakeng tsa 7 mm le 18.2mm (25 square millimeters le 150 square millimeters).

E ne e boetse e sebelisoa ho "li-insulators tse tloaelehileng tsa li-disc tsa bolo le mofuta oa socket" ka bophara ba pinana ea bolo ea 16 mm.

Ke Hobane'ng ha U Hloka Socket Clevis?

E le karolo ea bohlokoa ea lisebelisoa tsa pole, socket clevis e sebelisetsoa merero e itseng.

- E hokahanya insulator ea mofuta oa sokete le sekontiri sa tsitsipano kapa tšehetso.

- E sebelisoa e le e loketseng ho kopanya li-insulators tsa khoele e le 'ngoe.Mehlala e kenyelletsa "bolo le sokete, likhokahano tsa clevis le maleme, lipoleiti tsa joko bakeng sa li-insulator tse likhoele tse ngata."

- E ka boela ea sebelisoa lithapong tsa motlakase e le sehokelo sa motlakase.

- Melaneng e holimo, e sebelisoa e le karolo ea bohlokoa ea ho fana ka matla a motlakase ho literene, libese tsa trolley le literempe.

- Lithapong tsa phetiso, ke karolo ea sistimi e etselitsoeng ho thusa ho tsamaisa maqhubu a seea-le-moea.

Likarolo tse ka sehloohong tsa Socket Clevis

Socket clevis ke kopano ea likarolo le likarolo tse fapaneng.

Le hoja li fapane ka meralo le libopeho, tse ling tsa likarolo tse tloaelehileng ke tsena.

1. Mahlaahlela a ankora

Ke sekotoana sa tšepe hangata se bōpehileng joaloka U 'me se sirelelitsoe ka phini ea clevis le bolt.

Hape, e ka sireletsoa ho sebelisoa tšepe e nang le hinged loop e nang le mochini oa ho notlela oa ho koala kapele.

E sebetsa e le sehokelo se ka sehloohong lits'ebetsong tse fapaneng tsa khokahano ha li ntse li fana ka likhokahano tse potlakileng le ho li hakolla.

2. Clevis pin

Ke karolo ea bohlokoa ea clevis fastener e nang le likarolo tse tharo tse kholo tse kenyeletsang clevis pin, clevis, le tang.

Lithakhisa ke tsa mefuta e 'meli ho kenyelletsa le tse sa soasoang le tse khole.

Lithakhisa tse sa baloang li na le hlooho e bōpehileng joaloka dome ntlheng e ’ngoe ’me ka lehlakoreng le leng, ho na le lesoba la sefapano.

Ho boloka phini ea clevis e le teng, ho sebelisoa phini e arohaneng kapa phini ea cotter.

Pini e khole ka lehlakoreng le leng e entse lihlooho ka lehlakoreng le leng ha lehlakoreng le leng e le khoele feela.

Nate e sebetsa hantle ha phini e tlameha ho kenngoa.

3. Clevis bolt

E ka sebelisoa ho sebetsa sebakeng sa pin clevis le hoja e sa nke khatello ea kelello e tsamaisoang ke pin clevis.

Li etselitsoe ho nka le ho boloka meroalo ea tsitsipano.

4. Pini ea cotter

E boetse e tsejoa e le pini e arohaneng ho latela naha eo e sebelisoang ho eona.

Hopola, sena ke sekotoana sa tšepe se sebetsang e le sehokelo se nang le lipheletso tse kobehileng ha ho kengoa.

E sebelisoa ho kopanya likotoana tse peli tsa tšepe hammoho.

5. Bolt

Ke mofuta oa fastening o nang le likhoele tsa ka ntle tsa banna tse sebelisoang 'me o na le lintho tse tšoanang le screw.

Hangata e sebelisoa hammoho le linate.

Ka lehlakoreng le leng ho na le hlooho ea bolt 'me ka lehlakoreng le leng ke khoele e ka ntle ea banna.

6. Nut

Ena ke mofuta oa fastening o nang le lesoba le khoele.

E sebelisoa hammoho le bolt ho tiisa kapa ho kopanya likarolo tse fapaneng hammoho.

Tšebelisano e kopantsoe hammoho le motsoako oa likhoele ka khohlano.

Ntle ho moo, ho itšetlehile ka ho otlolla le ho hatelloa ha likarolo tse kopantsoeng hammoho.

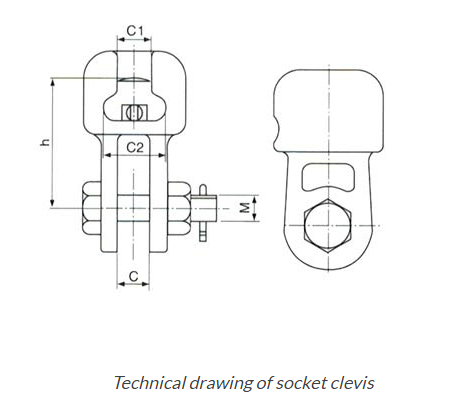

Tlhaloso ea Tekheniki ea Socket Clevis

Pele o reka socket clevis, ho bohlokoa ho ela hloko lintlha tse latelang tsa bohlokoa tsa tekheniki:

1. Mofuta oa Boitsebiso

Mofuta oa thepa e sebelisoang ho etsa li-socket cleviss ke tšepe le tšepe.

Lisebelisoa tsena li khethoa hobane li matla ka ho lekaneng 'me li khona ho mamella boima le likhatello.

2. Kalafo ea Bokaholimo

Li-socket clevise li fetisoa ka mokhoa oa ho etsa hore ho be le metsi a chesang ho etsa hore li se ke tsa bola.

Ho kenya letsoho ho kenya tšepe kapa tšepe ka har'a zinki ho e pata le ho e fa monko o monate oa ho qetela.

Tšepe le tšepe li hlatsuoa ka zinki e qhibilihisitsoeng ka mocheso oa likhato tse 449 tsa Celsius.

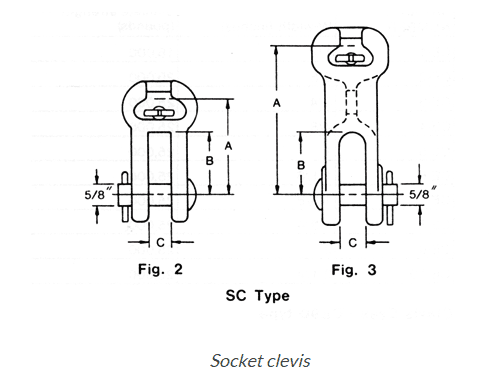

3. Litekanyo

Litekanyo tsa socket clevis lia fapana ho latela boholo ba sesebelisoa.

Hape, boholo ba socket clevis bo boholo ho feta litekanyo.

Bophara le bolelele li lekantsoe ka limilimithara ha boima bo lekantsoe ka lik'hilograma.

4. Moralo

Moralo oa socket clevis o ipapisitse le k'hamphani e e etsang.

Ka tloaelo, moreki o na le lentsoe mabapi le mofuta oa moralo oo a tla o hloka le bakeng sa mosebetsi oo o neng o tla o etsa.

Moralo oa socket clevis o tlameha ho ts'oana le mosebetsi oo o neng o reretsoe ho o etsa.

5. Rated Mojaro

Mojaro o lekantsoeng ho socket clevis o ipapisitse le boholo ba matla ao e tla sebetsana le ona.

Moreki o tlameha ho hlakisa mosebetsi oo clevis a tla o etsa pele a reka clevis.

Joale moetsi o tla eletsa ka clevis ea sokete e nepahetseng haholo mabapi le mojaro o hlophisitsoeng.

6. Boima ba 'mele

Boima ba socket clevis bo itšetlehile ka boholo ba sesebelisoa, thepa e sebelisoang ho etsa sesebelisoa.

Lisebelisoa tse ling li boima ho feta tse ling tse bakang phapang e kholo ea boima ba 'mele.

Litekanyo tse kang bophara, bolelele lia fapana le boima bo joalo.

Socket Clevis Manufacturing process

Ts'ebetso ea ho etsa tlhahiso e qala ka ho futhumatsa, ho bopa, ho kenya li-annealing ebe ka mor'a moo ho futhumatsa dip galvanization.

Mekhoa e boletsoeng ka holimo e kotsi 'me hangata e tloheloa hore liindasteri li sebetse.

Lisebelisoa: thepa e tala e hlokahalang ke tšepe le hlobo ea socket clevis.

Mechini e meng ea hlokahala bakeng sa ts'ebetso ena e theko e boima haholo.

Ke lona lebaka le entseng hore e tloheloe hore liindasteri tse kholo joalo ka Jingyoung li e etse.

Tlhokomeliso: Mokhoa oa ho etsa clevis o kenyelletsa ho tšoara tšepe ka mocheso o phahameng haholo.

Ke ts'ebetso e kotsi 'me u lokela ho ba hlokolosi haholo ha u tšoara tšepe e qhibilihisitsoeng.

Hape u lokela ho apara liaparo tse sireletsang le lieta ho u sireletsa likotsing leha e le life tse ka hlahang.

Litekanyo: Ena ke mokhoa oa ho fumana boholo bo nepahetseng ba thepa e tla sebelisoa ha ho etsoa tlhahiso.

E etsoa ho ea ka litlhaloso tsa moreki tabeng ea li-socket clevises tse entsoeng ka tloaelo.

Boitsebiso bo khaoloa ka likotoana tse hlokahalang pele bo behoa tlas'a mekhoa e meng.

Mokhoa oa ho futhumatsa: Tšepe ea cast e futhumatsoa ka mocheso o phahameng haholo hore e khone ho qhibiliha.

Cast iron ke ntho e ratoang haholo hobane e qhibiliha ka mocheso o tlase ha o bapisoa le tse ling.

E fetoha ho tloha ho se tiileng ho ea ho boemo ba metsi.

Tšepe e qhibilihisitsoeng e chesa haholo 'me tlhokomelo e ngata e lokela ho nkoa nakong ea ts'ebetso ena.

Ntle le ho qhibiliha ho tlaase, tšepe e entsoeng ka tšepe e na le metsi a matle, machinability e babatsehang, ho hanyetsa le ho hanyetsa deformation.

Mehaho ena e etsa hore e be thepa e ratoang ka ho fetisisa e sebelisoang ho etsa socket clevis.

Ho bopa: Joale tšepe e qhibilihisitsoeng e tšeloa ka har'a hlobo ea socket clevis.

Hlobo e bōpehile ka tsela eo e nang le lesoba le tšoanang le leleme la sekoti.

Mokelikeli oa tšepe o nka sebopeho sa hlobo e leng sebopeho sa socket clevis.

Annealing: Mohato oa boraro ke annealing e leng mofuta oa phekolo ea mocheso o fetolang microstructure ea tšepe.

Ke ts'ebetso e etsang hore socket clevis e fihlele matla a eona, ho thatafala, le ductility.

Ho phodisa: mohato oa bone o kenyelletsa ho tlohela tšepe e bōpiloeng hore e pholile.

Mokhoa oa ho pholisa o lieha ho lumella hlobo hore e lule e le teng 'me e se ke ea peperana.

Hot dip galvanization ke ts'ebetso ea ho qetela eo tšepe e pholileng e nkuoang ka eona.

Sena se kenyelletsa ho koahela clevis ea sokete ka Zinc ho e sireletsa hore e se ke ea bola.

Socket clevis e qoelisoa ka zinki e qhibilihisitsoeng ka mocheso oa likhato tse 449 tsa Celsius.

Mothating ona, socket clevis e se e lokile, 'me e ea hlahlojoa ho netefatsa hore e loketse ho sebelisoa.

U ka kenya Socket Clevis joang?

Ho kenya socket clevis ke ts'ebetso e hlokang hore lipalo li be teng pele u leka ho kenya.

Etsa bonnete ba hore lisebelisoa tsohle li teng le lere e teng ho u phahamisetsa bophahamong bo hlokahalang.

- Likhoele tsa insulator li lokela ho bokelloa fatše pele li hloa palo.Ho kopanya likhoele fatše ho bonolo ha ho bapisoa le ho e etsa ka holim'a palo.

- Li-insulators le li-fittings li boetse li kenngoa fatše le libakeng tse phahameng.

- Ho eketsa katleho ea ho kenya, haholo-holo ha maemo a kaho a le teng, kopano ea fatše e khethoa.

- Kopano libakeng tse phahameng li etsoa ha kaho e e-na le lithibelo.

- Nakong ea ts'ebetso ea ho kenya li-insulators le li-fittings libakeng tse phahameng, basebetsi ba nka lisebelisoa, liropo le litheipi tsa tšepe ho nyolohela lereng.

- Sebaka sa ho kenya letsoho la sefapano se tšoauoa 'me ka thuso ea thapo, se huloa.

- Letsoho la sefapano le kentsoe sebakeng ebe lisebelisoa tse ling tse kang insulator le likhoele tsa insulator li kenngoa.

Socket clevis ke karolo ea bohlokoa haholo ea li-pole line hardware mme e kentsoe ke litsebi.

Mofuta oa mosebetsi oo e lebelletsoeng ho o etsa o hloka hore batho ba nang le boiphihlelo ba o kenye kaha liphoso ha li amoheloe.

Hape ho kotsi haholo ho leka ho kenya ntle le thuso ea batho ba bang ho bolelang hore e ke ke ea etsoa ka bomong.

Nako ea poso: Sep-17-2020